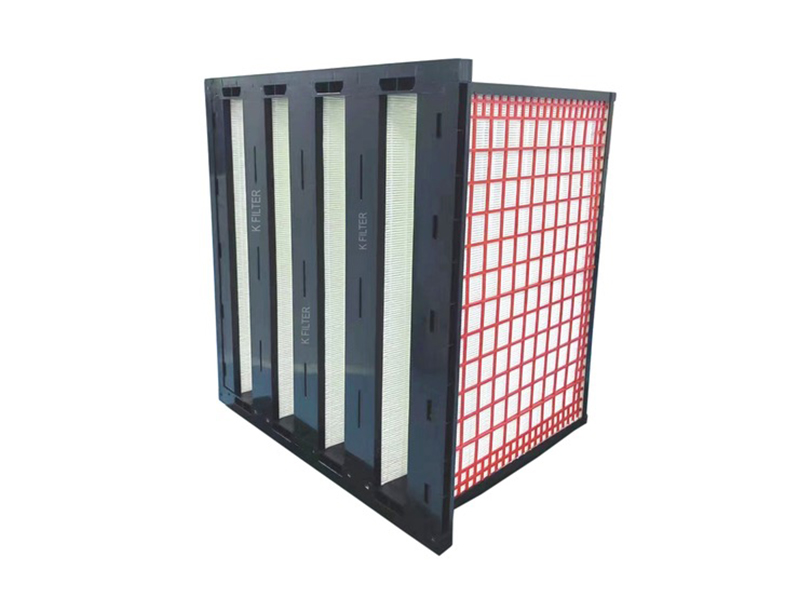

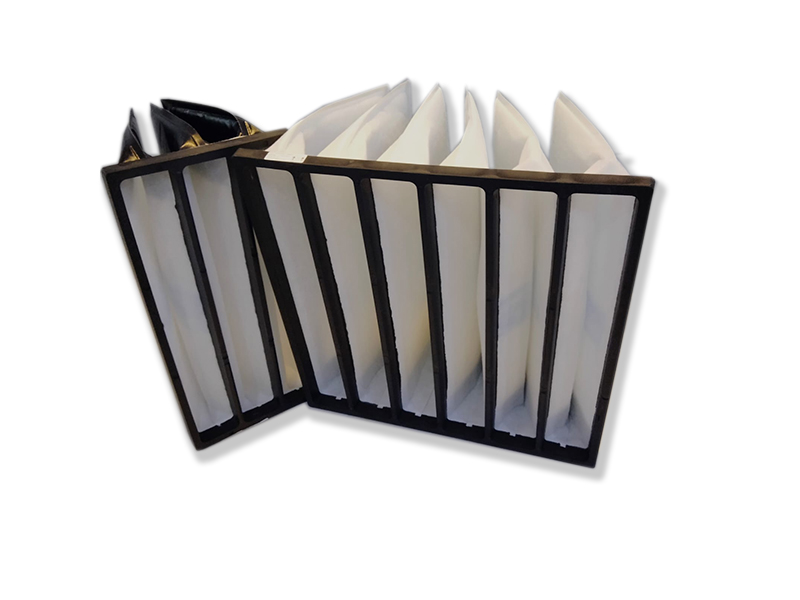

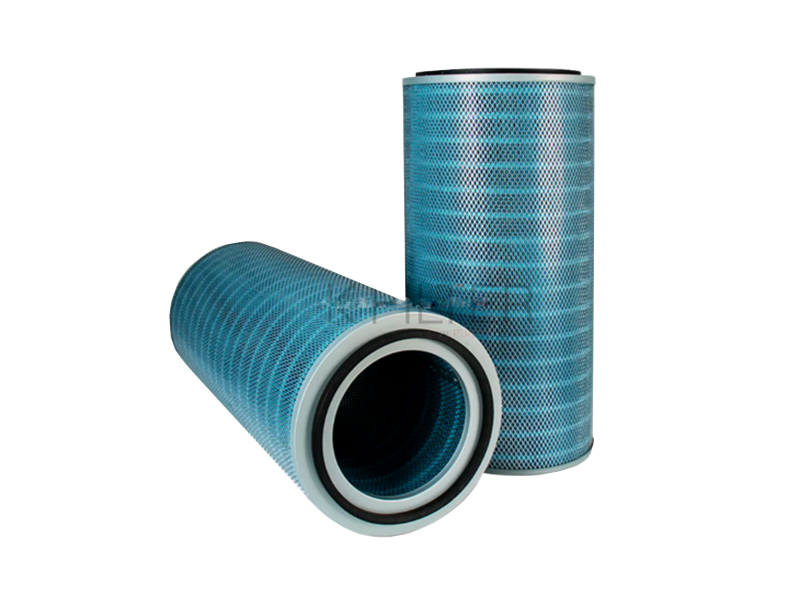

Gas Turbine Air intake Filter

Gas turbines need air and fuel for combustion such as a natural gas (NG) which contains approximately 94% of methane. Air is one of the main inputs to the Gas turbine (GT)for combustion Filter designs and manufactures high efficiency Gas Turbine Air Intake Filters (AIF) can deliver clean air of the axial air compressor and the longer life cycle of the Gas Turbine (GT) hot gas path help to lower maintenance cost and down time.

Gas turbine (GT) combined cycle or simple cycle (SC), Steam Turbine (ST), Heat recovery steam generator (HRSG) air intake filter for power generation industry plays very important role as it helps to purify the air intake, which is one the main three components (fuel, air, heat), which convert chemical energy to mechanical energy. As air and fuel are the two main sources of combustion, quality of the air ingested by the GT air compressor plays very important role.