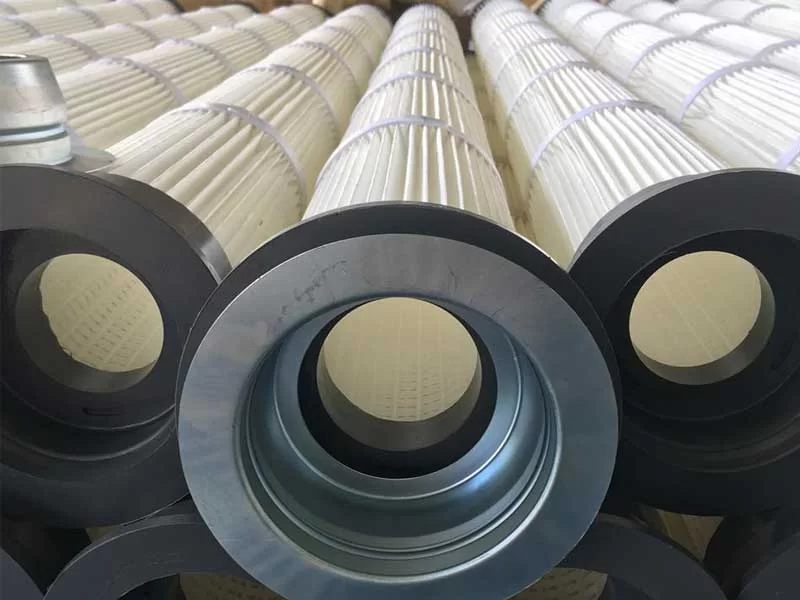

Long Pulse Jet Filter Bag (Pulsate Series)

The long pulse jet filter bag is easy to self-clean and supported with PU, galvanized, stainless, metal configuration promising high filtration efficiency. The design feature is the top is an open type and the bottom is a close type allowing various ways of flange installation. Different compositions for media are available such as polyester, polyester + Flame retardant, polyester +oil, water-resistant, polyester + antistatic and Polyester + PTFE membrane.The industries where long pulse jet filter cartridges have a smart chair are coal mill, fly ash silo, surge hopper, limestone, powder coating, rice bran process, plasterboard production line, calcium carbonate transfer, fertilizer production process, fertilizer production process, cement concrete process, marble process and casting grinding. K FILTER Polyurethane (PU) pleated filter bags have a flexible PU top and bottom and these bags are inserted in the system as a “top loader”. Each bag is provided with a metal plug to be inserted inside the PU top and the PU expands because of the metal plug and seals the bag at the cell plate. These bags have a max temperature limitation of 90°C.

FEATURES

-

- Narrow pleat width

-

- Easy to self –clean

-

- High filtration Efficiency

-

- 3time more filtration collate to filter bag

-

- Top open, bottom close type

-

- PU, Galvanized, stainless, metal configuration

-

- Various ways of flange installation

APPLICATIONS

-

- Coal dryer dust collector

-

- Coal mill

-

- Fly ash silo

-

- Surge hopper

-

- Lime stone

-

- Powder coating

-

- Rice bran process

-

- Plaster board production line

-

- Calcium carbonate transfer

-

- Fertilizer production process

-

- Cement concrete process

-

- Marble process

-

- Casting grinding

CONSTRUCTION

| Media | Polyester + Flame retardant,Polyester +Oil, water resistant,Polyester + Antistatic,Polyester + PTFE membrane |